Metal Spinning

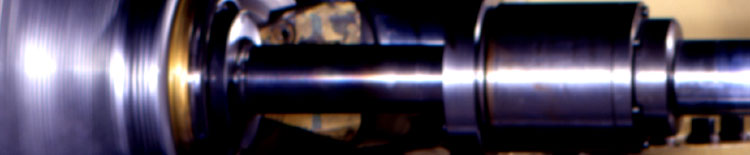

Metal Spinning is a unique process used for shaping seamless, hollow sheet metal parts using the combined forces of rotation and pressure. Practically any metal that can be worked can be spun. In fact, some metals and shapes are easily spun that cannot be drawn or formed by other methods. Spinning is ideal for applications where there is a demand for absolute structural integrity, a minimum number of components, or a requirement for the use of advanced materials.

Metal spinning is an excellent method to consider in conjunction with other forming methods to produce parts and shapes. Spinning can replace many of the initial forming steps required for drop-hammer or hydro-forming, thus saving time and money.

Flexibility in Part Design

There are few

limitations on spinning designs, even out-of-round shapes can be

spun. Ideal parts are hemispheres, cones, domes, and re-entrant

shapes.

Part Strength & Integrity

Wall thickness is controlled throughout the part, which prevents excessive thinning of the metal. Grooves can also be added either internally or externally to increase stiffness.